The development of dies is an important part of the services provided by PMT. It is at the core of every creation. A great deal of care and accuracy is invested in the development of every die. Our challenge is to turn every idea into a high quality injection moulded product. The know-how accumulated over the years allows us at PMT to find solutions to any creative or complex question.

Maintenance and storage of dies

PMT makes sure your die is stored safely and securely. Above all, this minimises the risk of damage during transport and ensures that your die can be put to work at any time thanks to our flexible production flow. In addition to storage, your precious die requires maintenance, also a vital aspect. Consequently, PMT offers a very high quality maintenance package where adjustments can be monitored very closely and performed by our expert staff.

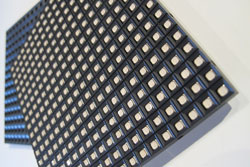

Some of our references

Injection moulding is a process whereby plastic is liquified and injected under high pressure into a mould; the resulting products can take all kinds of shapes and colours. Injection moulding is often a solution to many problems in a variety of sectors and this is where PMT shows its worth as a full partner. PMT is synonymous with high quality. Our state-of-the-art machinery and automation policy reflect our company’s in-house strategy. PMT will consistently supply each product with the same level of quality, whether manufactured in small or large quantities.

- Our fleet consists of several machines that can provide answers for each question, our machines have a clamping force of 20-470 tons.

- Materials: : ABS, ASA , HDPE, HIPS, PA6, PA6.6 , PAA, PA+CF, PA+GF, PA+PTFE, PBT, PC, PC/ABS, PC+PTFE, PET, PF, PMMA, POM, PP, PPA, PPO, PPS, SAN, SEBS, SPS, TPE

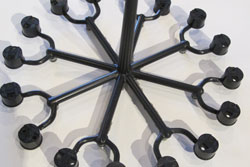

Some of our references

Support during and post production is an important dimension of PMT’s service. Final processing plays a major role in this. At PMT we can take are of various finishing processes, both automatically and manually. This includes the assembly of plastic products into semi-finished or finished product. Indelible printing or in-mould labelling are also within our capabilities. PMT will be happy to study solutions with each customer and offer a total solution that will cover both assembly and bespoke packaging.

Some of our references

PMT has its own warehouse and is therefore able to store and manage your products. Our sophisticated management system allows us to act quickly and offer you a perfect logistics service. We will organise your route from A to Z entirely internally, and with the utmost care for quality and service. PMT has had very loyal logistics partners for years, for which punctuality and transporting your products with the utmost care is paramount.

Some of our references